I would have updated this before, but I've had problems uploading photos, but the size issue is resolved now, so here's a historic update...

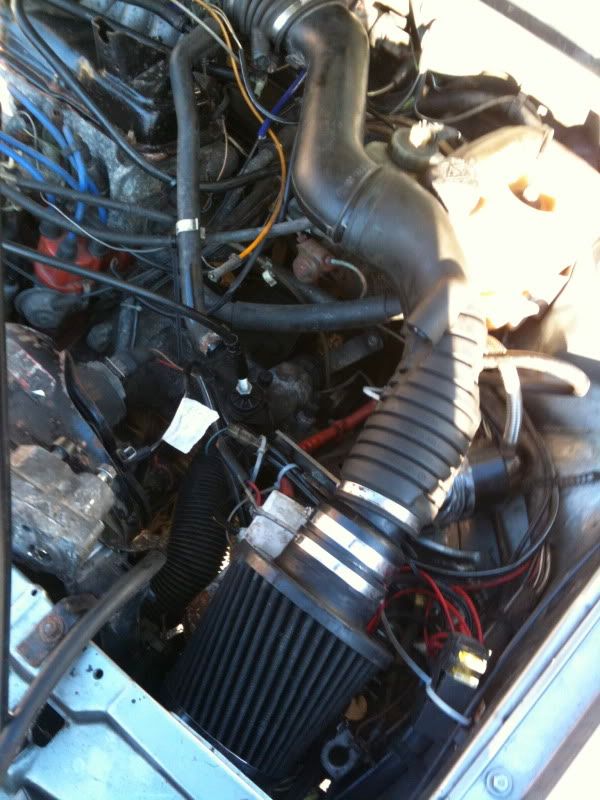

The rough spec is

- 2.0 8v engine - reputed to be the ex Claire Tippet VW cup engine (and I've no reason to doubt this), running on Kjet instead of carbs.

- Koni Sport suspension kit, and poly bushed all round.

- 280mm G60 discs, and rear disc conversion, Goodridge hoses. Willwood bias valve.

- Partly stripped interior

- The shell is a bit scruffy in places, where the previous owner's graphics were removed, but I view a shell as expendable on a track toy, as long as it's straight and solid, that's fine.

It's first trackday with me was at Curborough - need some stiffer ARB's!!

and I did a navigational rally in 2009.

The previous owner used to do Autosolo events in it

http://www.youtube.com/watch?v=0DGmmQnyMU0

So far I've done some fettling to get the car to a decent roadgoing standard:

- Fitted an oil cooler, and replumbed the cooling system, so you don't have to leave the heater full up to get coolant flowing round the engine!

- Changed the burnt out ignition switch

- Fitted an uprated headlight loom and bulbs

- Fitted a lower front strut brace

- Changed the wheels for some that actually fit the car (without rubbing the arches).

- Checked the mixture and timing - fitted a 16v WUR to get the engine running a bit better

(Air:Fuel Ratio went from 14:1 to 12.5:1, with no other changes)

- Fitted an oil pressure gauge, which thankfully gives me good news!

Much more to follow:

Next jobs:

- Fix the driveshaft(?) that's knocking

- Find the knocking engine mount and replace.

- Fix the fuel filler neck, which has just started seeping.

- Optimise the mixture and timing a bit more.

- Fit some better seats.

- Uprated ARB's

- Sunroof out (15kg?)

- Plastic Windows

- Stud and wheel nut conversion

- Extra oil cooler.

More jobs I remembered...

- Fit supersprint exh manifold instead of the Ashley that's on there!

- Battery in the back

- Fit racing master cylinder and delete the servo/brake linkage (10 kg?)

- improve intake tract

In the past I've tended to spend too much time working on cars, and not enough time driving it. I'm aiming to enjoy it this summer, and then take on some bigger jobs.

- Megasquirt conversion on the 8v

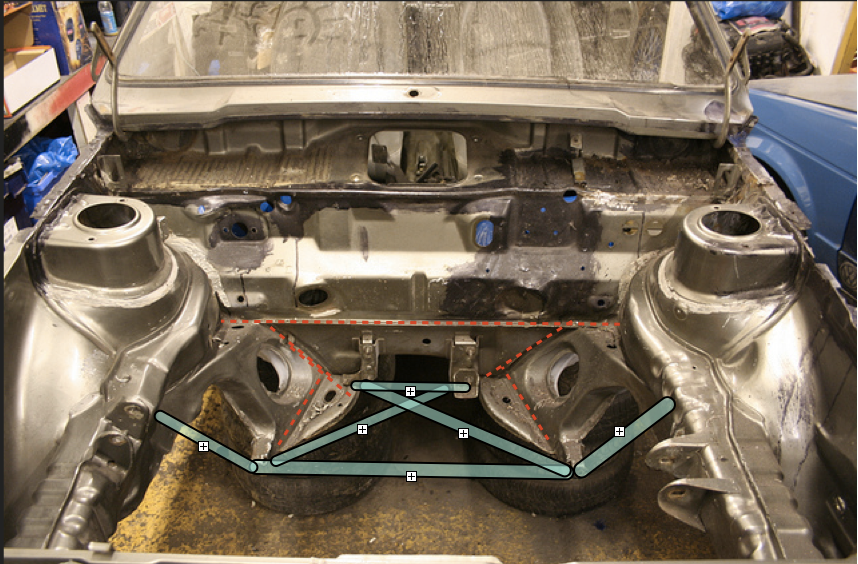

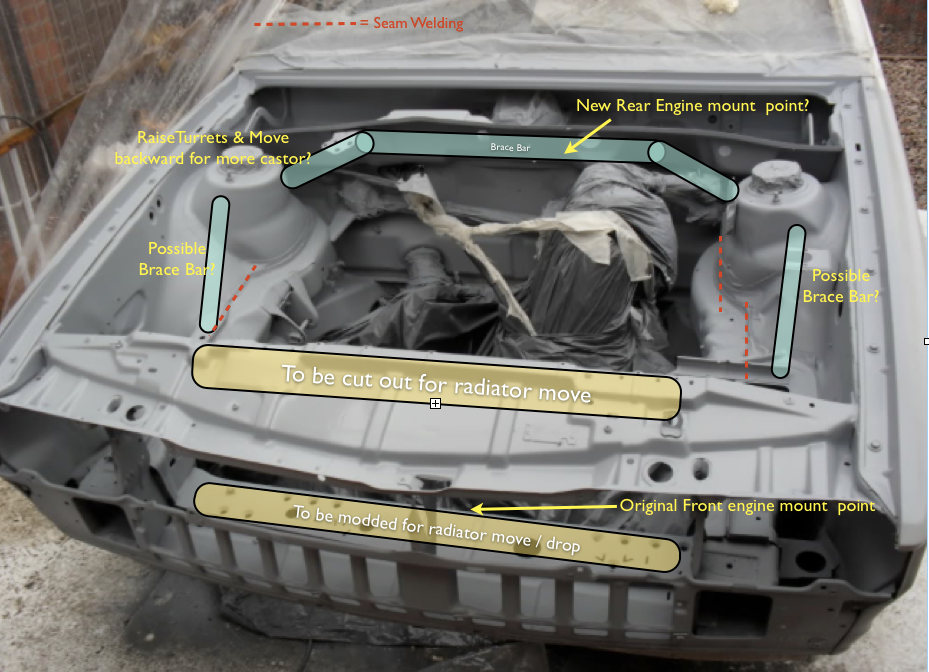

- Rollcage

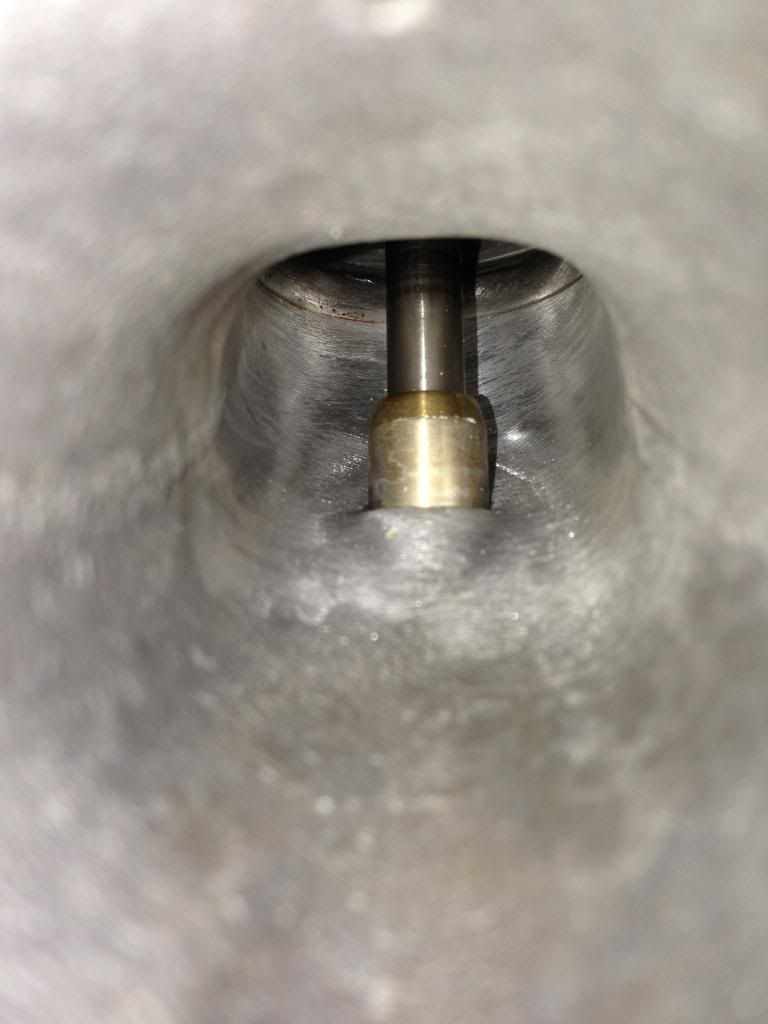

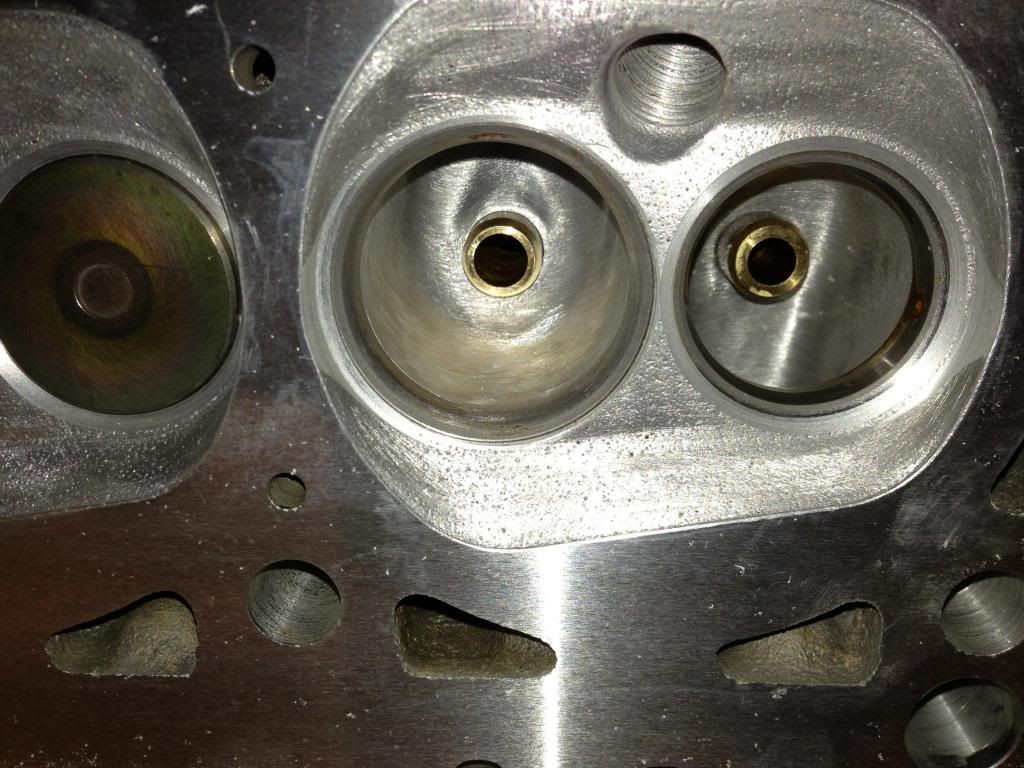

- Eventually, a 2.1 16v lump, that I've been buying uprated bits for.