Quick update on state of play...

This is probably the most its ever looked liked a car again! front end fitted up and seats etc all in, starting to take shape.

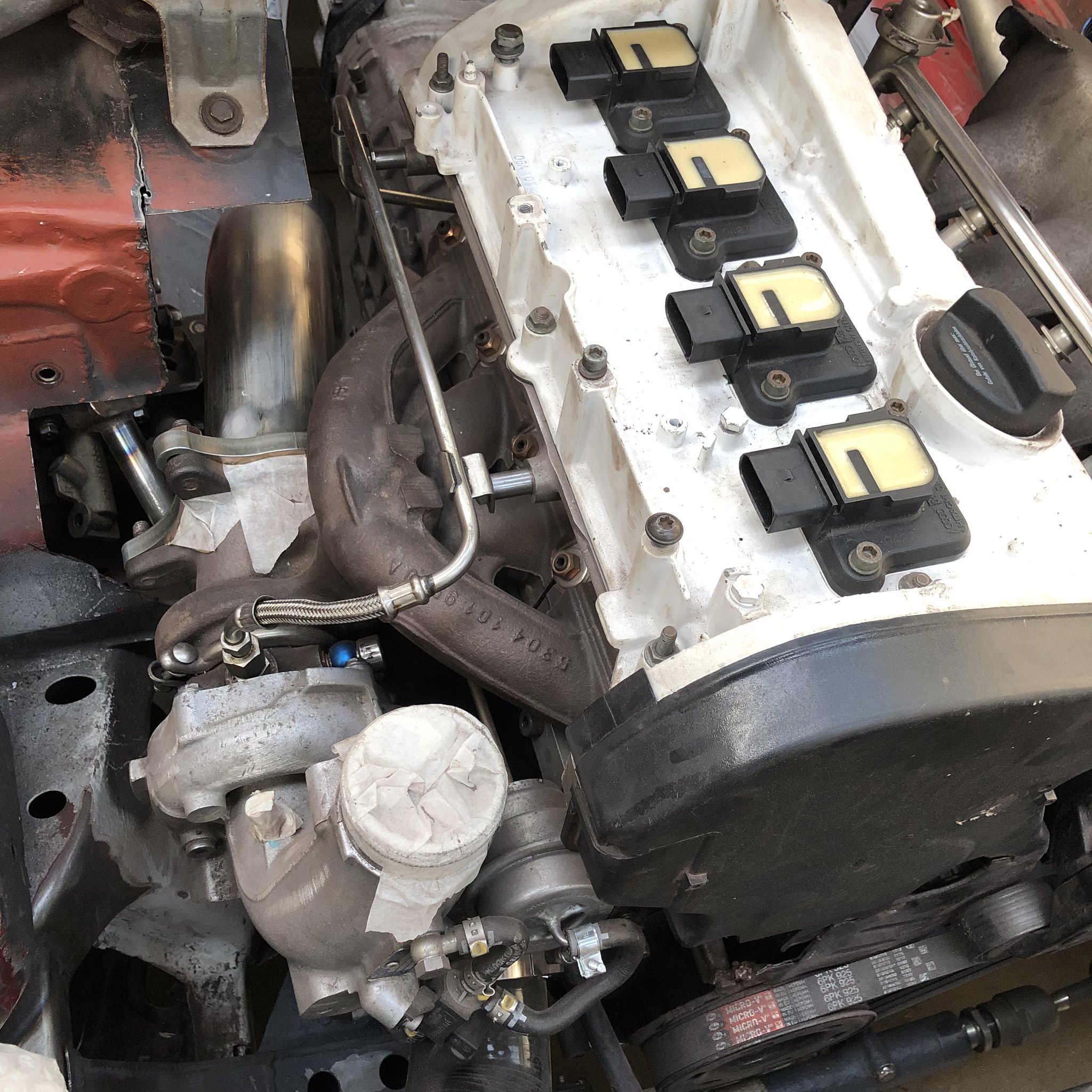

Been focusing on the engine bay side of things, modified sump and pickup pipe are now done and on the car running two magnetic drain plugs for the sump, B6 A4 rocker cover has AN-12 take off for catch can system, massive pro-ram cone filter plumbed up with 90mm -> 60mm pipework with DV relocating into the FMIC pipework, running an ARF baffled catch can mounted to the inner wing, starting to come together nicely!

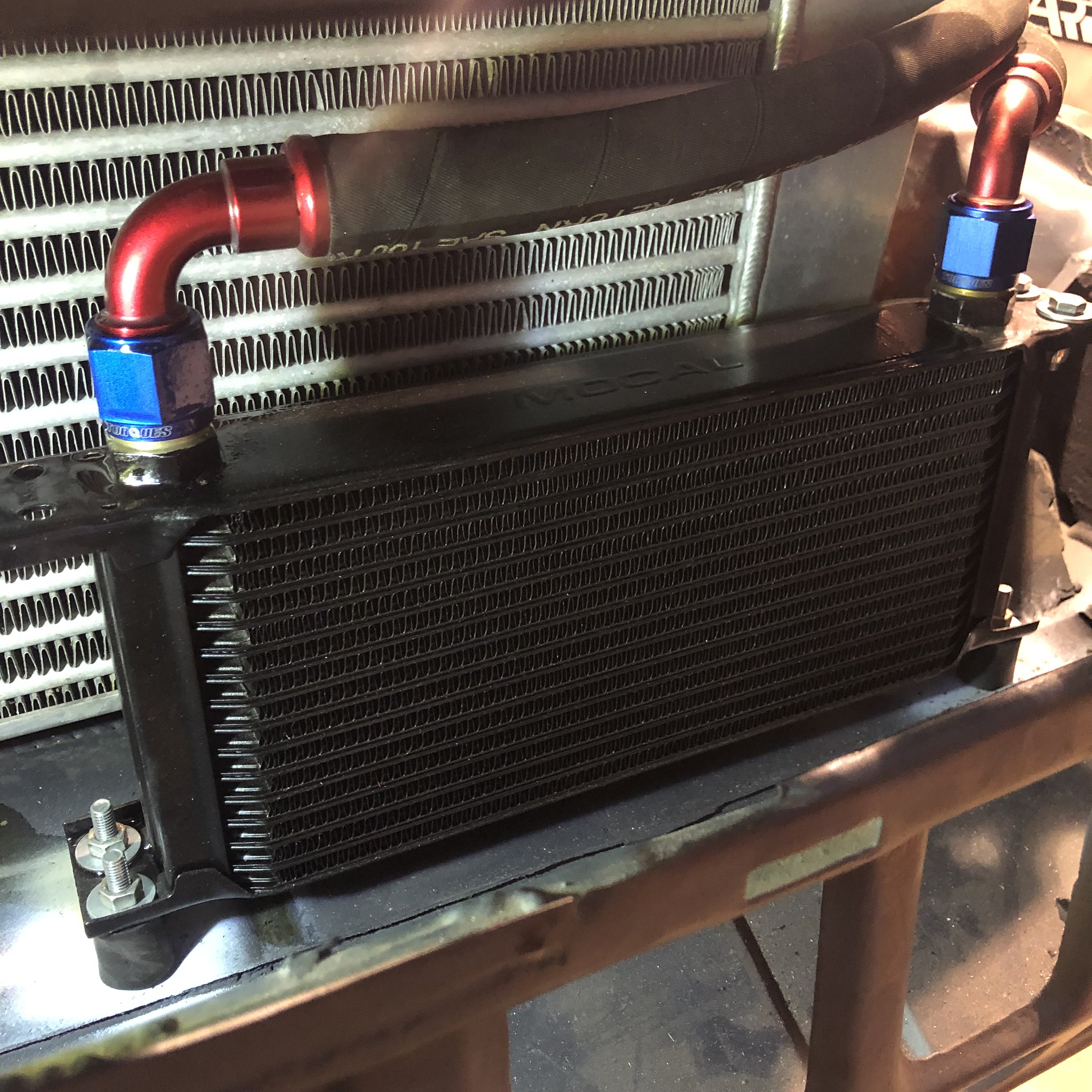

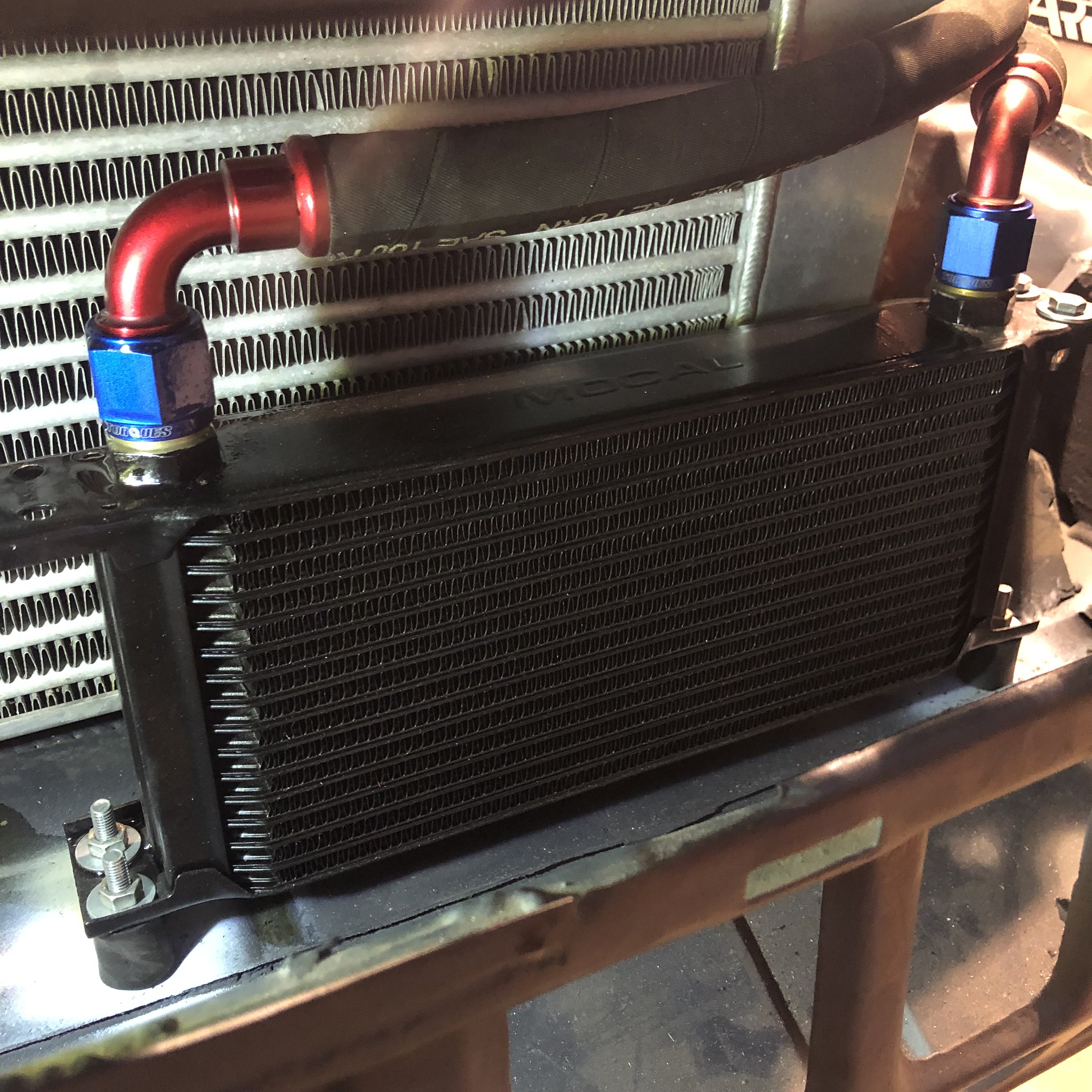

16 row AN10 Mocal oil cooler mounted up front

Mocal oil cooler thermostat sandwich plate and mocal relocation plate with a 1/8 NPT take off for oil temp gauge (got my pressure gauge hooked up for now for first start up) for remote oil filter

Allows me to run this beast of an oil filter, T4 2.5 diesel van, massive!! Also very very easy to access for future oil changes.

Pipework for the oil system, all AN10 push on style fittings with oil rated hose

This brings the total oil capacity to just over 6L give or take, despite having to remove a bit from the sump, very happy with that!

Downpipe version 2 tacked together, this is going to need to change slightly again, more on that in the next update!

It basically needs to run tighter to the gearbox especially at the bellhousing section to make for some more space around the pedalbox area.

Now, sussing out the flywheel, starter, clutch, spigot bearing etc!

After notching the bellhousing a bit to allow the starter to fit i have the following combo:

Audi A4 B5 1.8t flywheel, starter and pressure plate

2.0 Ford Pinto clutch disc (just for testing!)

Rx8 slave cylinder, clutch arm, release bearing etc

I've plumbed and bled the clutch and it looks like this setup will work after a small bit of tweaking to allow for a little bit more play in the clutch fork. Obviously I will go for uprated components for the final build to handle the torque of the 20vT, this is just for proof of concept!

Ford Type 9 spigot bearing fits a treat as the VW crank is 21mm bore and the rx8 input shaft 15mm, exact same as the ford dimensions!

Gearbox mount version 4! This one is nice and compact and uses some old mk2 escort anti tramp bar bush ends welded to an offcut from the seat rails, i've pressed in new tramp bar polybushes. This is then welded to an 8mm plate i fabbed up to bolt to the back of the rx8 box.

this all then bolts in to 2 'bolt on' brackets that bolt to the inside of the tunnel via plates with captive nuts that i've made up and welded to the inside.

Nice and strong and makes removing the box much easier now! and i can fit a 3" exhaust under the mount too.

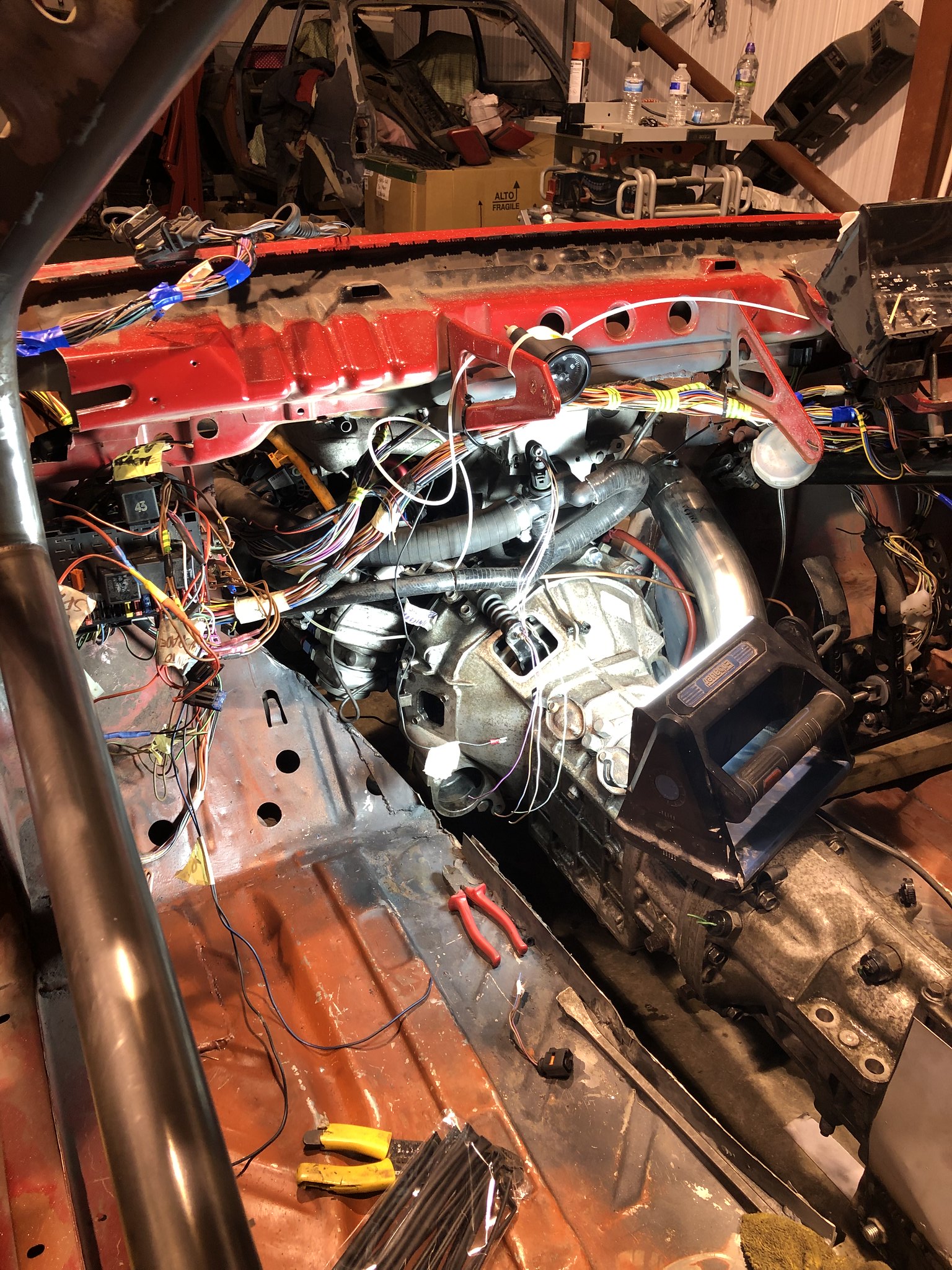

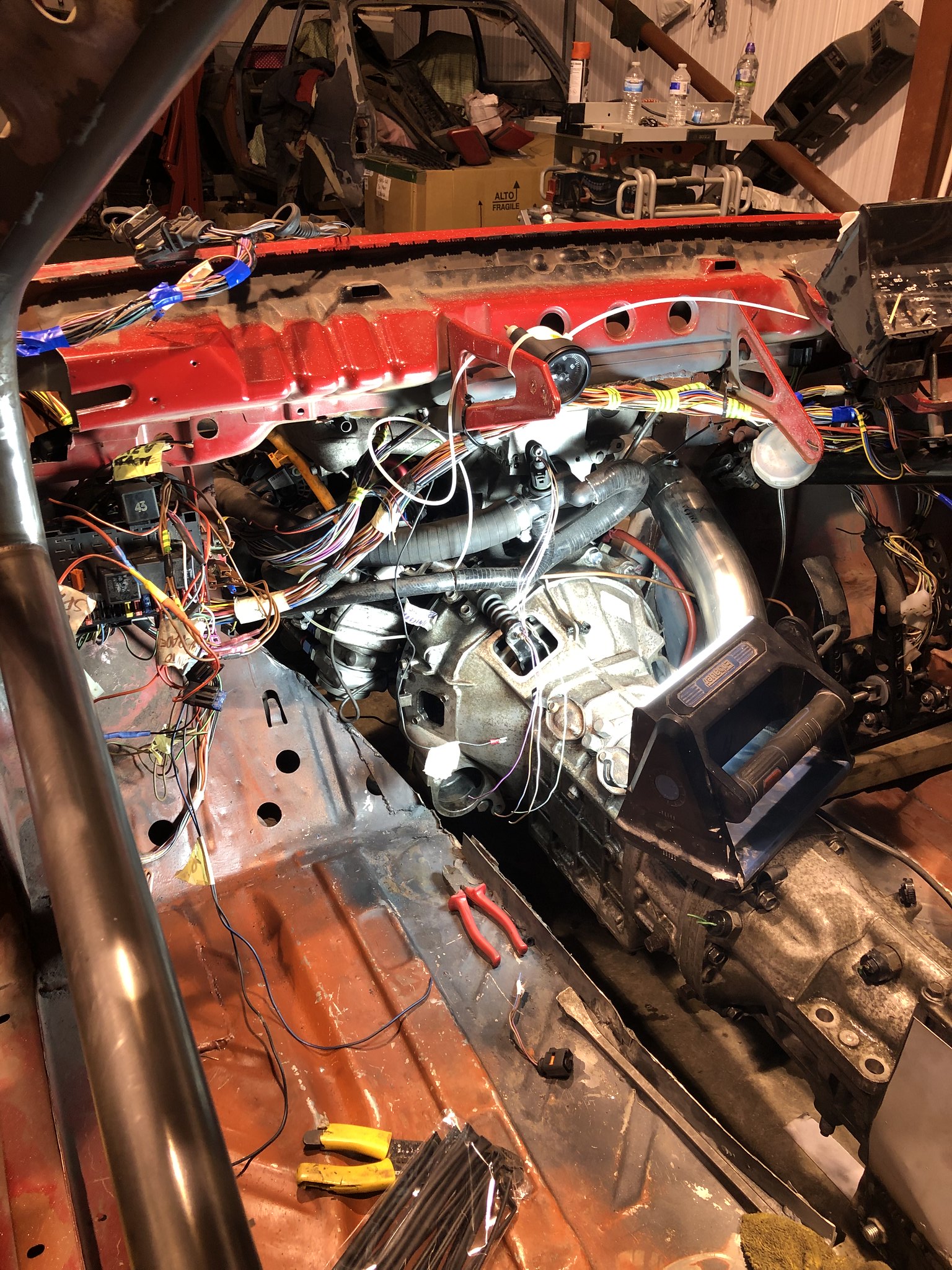

Right, time to chuck some wiring in, hook up some fuel lines, set up a very rough base map on the emerald and see if she will start up!

First of all, my butchered ce1 1.8T engine loom i made up previously had been cut up a bit for some bits on my other car so this needed rectified first.

Mainly adding new plugs for starter, new TFSI n75 wiring, injector wiring, map sensor, and eventually the 4 pin coils (although im going to start it up on the 3 pin coils first)

Reverse lights working with the RX8 box!

Fuel lines are exactly as they were before (now far too long!) and fuel system also as it was, facet lift pump feeding swirl pot, inline filter then bosch 044 pump up to the rail.

Of course, this is all temporary just for starting it up, proper brackets, fuel cell etc will be used!

Quickly calibrated a rough map on the Emerald ECU and after robbing a couple relays from my daily car I was ready for the first fire up.

CRanked it for about 15 seconds and nothing, pumps had primed but im presuming had only filled the swirl pot.

Next crank she fired a bit...

Next crank she fired right into life on all 4's and idled away lovely!! Get in.

Oil pressure reading nice and high on the gauge, lambda readings a bit high but then again my downpipe is only tacked together, also no gasket or anything.

put it up on the lift and tried a few gears while operating the clutch pedal by hand, 1st good, 2nd good, 3rd good!! rear wheels were going like mad so didn't go any more than that.

Beyond chuffed with it, she is now officially Rear wheel drive!

Here are the latest youtube videos that go a little more in depth on what I've done.

Oil system and engine bay

https://www.youtube.com/watch?v=ToAt7OGWfbw

Clutch, flywheel, spigot bearing, starter, etc etc

https://www.youtube.com/watch?v=PN4dGS6xkpM&t=7s

The first start up video will be coming out this weekend hopefully!

Thanks for reading. Daz