Page 1 of 1

cutting back rear arches for wheels

Posted: Thu Jun 11, 2015 9:41 am

by steve bain

so my rear arches are a bit crispy and need repairing and i want to space my rear wheels out to the edge. Whilst i am there i want to slice the lip off at the top from about 10-2 as i have done on the front and then rejoin the inner and outer arch. I was planning on seam welding the edge and grinding smooth, but someone has suggested just tack welding every 50mm or so and pumping a load of pu adhesive in from above to glue the 2 lips together and avoid potential distortion. seems like it may be a rust trap though.

This is on a bodykitted car and like i say a lot of the lip is already missing. obviously i will also slice the bodykit and adhere it where i have cut off the mounting points.

I can weld and seam welding feels like the correct option. any thoughts? originally it is only spot welded, so maybe seam welding is a bit ott.

Re: cutting back rear arches for wheels

Posted: Thu Jun 11, 2015 11:07 am

by Little_bro

I would tack on first then weld it. I'm sure your not allowed to tack weld only with the mot

Re: cutting back rear arches for wheels

Posted: Thu Jun 11, 2015 7:40 pm

by the edmundator

I agree with your thoughts about it being a rust trap if you don't do it properly - especially in one of the wettest/dirtiest areas on the car.

Re: cutting back rear arches for wheels

Posted: Fri Jun 12, 2015 12:18 pm

by Blueshark

I would take out the old crispy arches, then put in a new set which I would then place slightly more out to widen it all. But welding properly must be done because it is a part of the body strength and not welding it as it should and glueing it a bit would give you handling problems with torq and so on.

Joost

Re: cutting back rear arches for wheels

Posted: Fri Jun 12, 2015 11:17 pm

by james butler

cant you just cut the arch in 1-2" intervals between spot weld and fold it in on itself thus avoiding deforming the arch and maintain some rigidity?

Re: cutting back rear arches for wheels

Posted: Tue Jun 23, 2015 9:39 pm

by Nate

Needs to be a continuous weld for mot

Re: cutting back rear arches for wheels

Posted: Wed Jun 24, 2015 9:50 am

by Blueshark

james butler wrote:cant you just cut the arch in 1-2" intervals between spot weld and fold it in on itself thus avoiding deforming the arch and maintain some rigidity?

Is not going to work because it ist als pointwelded to the innerarch, so you would have to cut that as well and put in a strip to fill up the gap between inner and outer arch after bending outwards.

Joost

Re: cutting back rear arches for wheels

Posted: Wed Jun 24, 2015 12:03 pm

by steve bain

this sounds like it could be confusing!

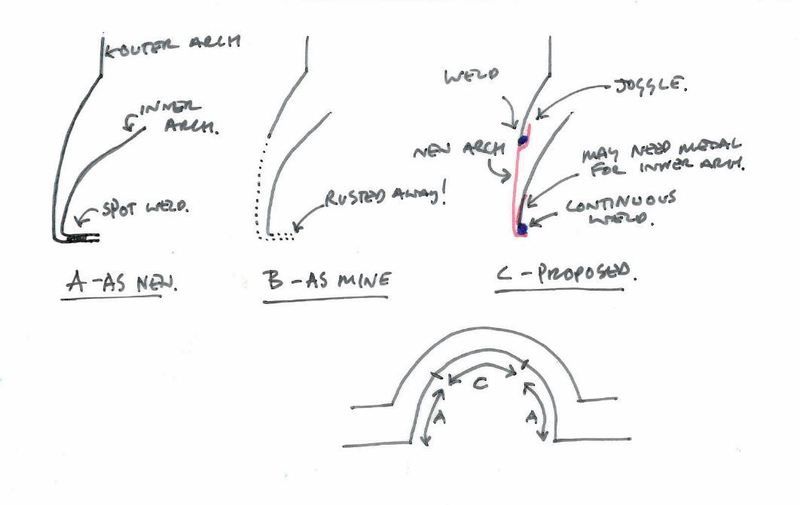

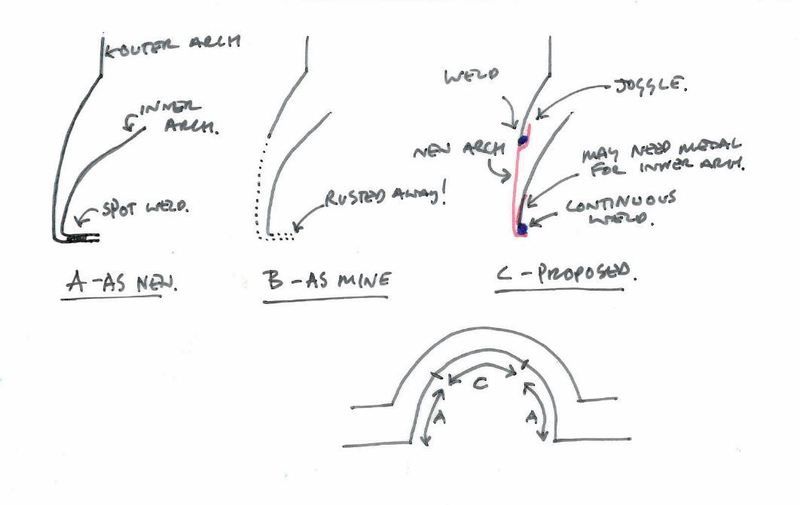

i did a drawing. this is my plan. it retains the folded lip to the outer arch so should reatain its shape. I will then patch inner arch as required and weld to the outer arch between 10 and 2. the other areas i will prob do as original so i have something to fix the body kit to!

Re: cutting back rear arches for wheels

Posted: Fri Jun 26, 2015 2:24 pm

by james butler

Blueshark wrote:james butler wrote:cant you just cut the arch in 1-2" intervals between spot weld and fold it in on itself thus avoiding deforming the arch and maintain some rigidity?

Is not going to work because it ist als pointwelded to the innerarch, so you would have to cut that as well and put in a strip to fill up the gap between inner and outer arch after bending outwards.

Joost

I'm not sure I understand what you mean?

I wanted to roll my arches but the arch is tough to bend in. So I cut 1mm slots in the arch lip so it would be easier to roll 2 inch pieces of arch than the whole thing in one go.

All of the original spot welds holding the outer archer to inner lip are intact.

Is this ok or are you saying the 1mm slits need welding?

Re: cutting back rear arches for wheels

Posted: Fri Jun 26, 2015 2:40 pm

by james butler

I think your idea will work Steve as long as you have a continuos weld because in essence you have no arch lip left.

Looking at your drawing I didn't realise you were going to cut it all off and weld up the edge.

Hence why I thought you could just roll them back after spot welding

Re: cutting back rear arches for wheels

Posted: Sun Jun 28, 2015 8:04 pm

by steve bain

It all done now and works. Good times. I just need to finish the welding. Seam welding is so slow with no heat!