Re: 1985 GTX barn find + 1991 GT2 20VT!

Posted: Sun Mar 19, 2017 9:00 pm

do it now whilst they are still reasonably cheap

The official forum for the Scirocco Register

https://forum.sciroccoregister.co.uk/

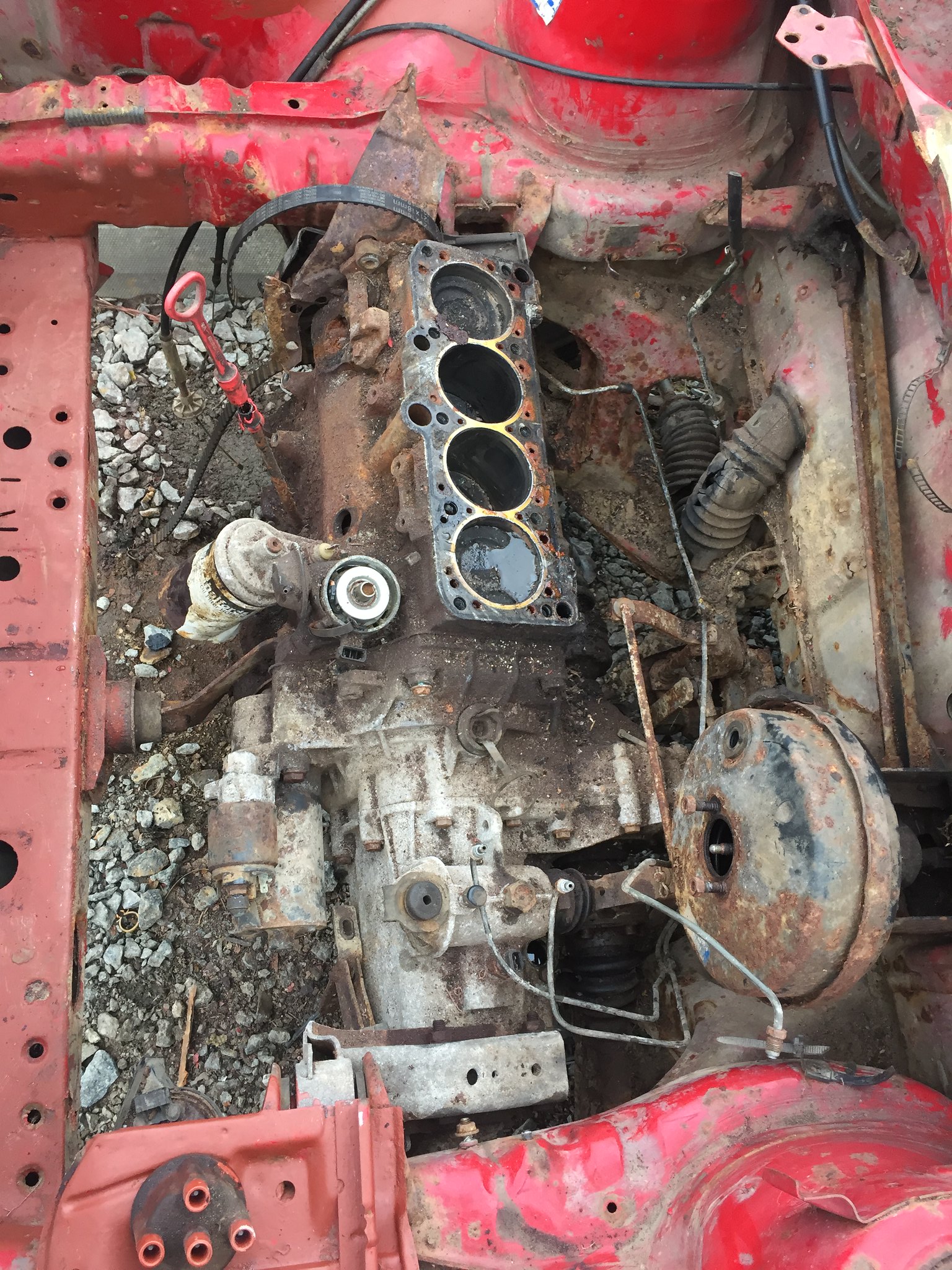

Rocco resto by Darren Ellis

Rocco resto by Darren Ellis Rocco resto by Darren Ellis

Rocco resto by Darren Ellis Rocco resto by Darren Ellis

Rocco resto by Darren Ellis Rocco resto by Darren Ellis

Rocco resto by Darren Ellis Rocco resto by Darren Ellis

Rocco resto by Darren Ellis Rocco resto by Darren Ellis

Rocco resto by Darren Ellis Rocco resto by Darren Ellis

Rocco resto by Darren Ellis Rocco resto by Darren Ellis

Rocco resto by Darren Ellis Untitled by Darren Ellis

Untitled by Darren Ellis Rocco resto by Darren Ellis

Rocco resto by Darren Ellis Rocco resto by Darren Ellis

Rocco resto by Darren Ellis Sound deadening removal by Darren Ellis

Sound deadening removal by Darren Ellis Sound deadening removal by Darren Ellis

Sound deadening removal by Darren Ellis Sound deadening removal by Darren Ellis

Sound deadening removal by Darren Ellis Sound deadening removal by Darren Ellis

Sound deadening removal by Darren Ellis Sound deadening removal by Darren Ellis

Sound deadening removal by Darren Ellis Sound deadening removal by Darren Ellis

Sound deadening removal by Darren EllisRegardless, strengthen that area anyway.mk2daz wrote:... Im really happy as the clutch cable exit in the bulkhead is really solid...

steve bain wrote:i agree, it will pull through eventually and whilst the engine is out it makes sense. you'll find loads more of those little holes when you start poking about!

mark1gls wrote:I guess it depends on what clutch/gearbox you will be using, if going with a hydraulic clutch system then here's no need to worry about strengthening the bulk head but if using the original clutch cable system then do strengthen it as it's a really bad design by VW and it will crack at sometime in its life.

agreed everyone! The plan is 20vt with hydraulic clutch however if that idea changes then this will be strengthened for sureDT1 wrote:Regardless, strengthen that area anyway.mk2daz wrote:... Im really happy as the clutch cable exit in the bulkhead is really solid...

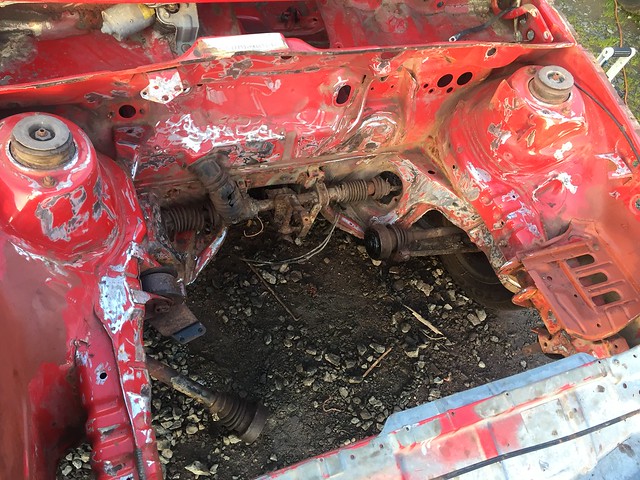

https://flic.kr/p/VXAgg3 by Darren Ellis

https://flic.kr/p/VXAgg3 by Darren Ellis https://flic.kr/p/WCunBU by Darren Ellis

https://flic.kr/p/WCunBU by Darren Ellis N by Darren Ellis

N by Darren Ellis https://flic.kr/p/XaAdUS by Darren Ellis

https://flic.kr/p/XaAdUS by Darren Ellis https://flic.kr/p/W1614t by Darren Ellis

https://flic.kr/p/W1614t by Darren Ellis https://flic.kr/p/WCuNwo by Darren Ellis

https://flic.kr/p/WCuNwo by Darren Ellis New passenger door by Darren Ellis

New passenger door by Darren Ellis New passenger door by Darren Ellis

New passenger door by Darren EllisYeah! Thanks for all your advice over Facebookjames butler wrote:was looking through this thread thinking this looks familiar and its just clicked lol

i see what you mean the rot has really eaten into the handle area but you`ve given it a valiant effort.

I started to understand how to do this as I was coming to the end of the weld, might have another go at it soon, but at least I have a good door to fit anyway, cheers!steve bain wrote:I find when welding in the gaps between the spot I overlap the last weld and do a blob, wait a second and do it again. The mass of the previous weld stops blowing holes. Also nice tight joints. Trying to fill gaps on bodywork is hard work! Keep going though....

Rocco by Darren Ellis

Rocco by Darren Ellis Rocco by Darren Ellis

Rocco by Darren Ellis